This article outlines the process for accepting returns within a main hub environment using The Return integration with Connect and SPOT. It assumes that your store has already been provisioned and configured with the necessary settings to begin processing returns efficiently.

Driver Drop-Off

Upon the consolidation driver arriving at the HUB store location, all packages must be inspected and accounted for.

If visible damage is found, it should be noted on the driver’s manifest.

The physical inventory must be reconciled with the printed manifest, to ensure the accuracy of the number of packages received.

Should the piece count not match, the envelope of invoices printed from the Sub store should be used to find the missing, physical package.

Processing Third-Party Drop-Offs

If processing a third-party drop-off, the staff must use Connect to process the Return Label, just as they would at a sub store location.

To review the process to enter a new return through Connect, you can review our Sub store processing article here.

Processing Hub Drop-Offs

To process HUB drop-offs, whether the return was processed at the Hub location, or picked up from a Sub Location, the 2D QR codes must be scanned into the appropriate workflow step.

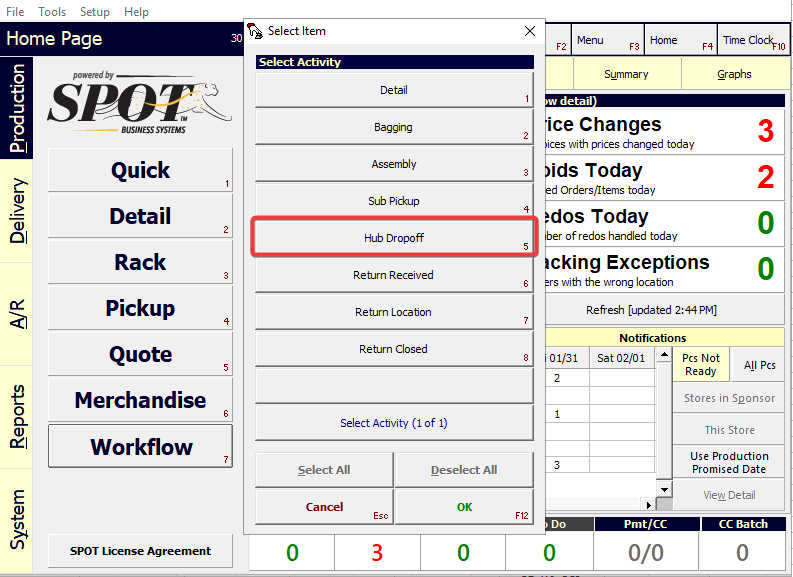

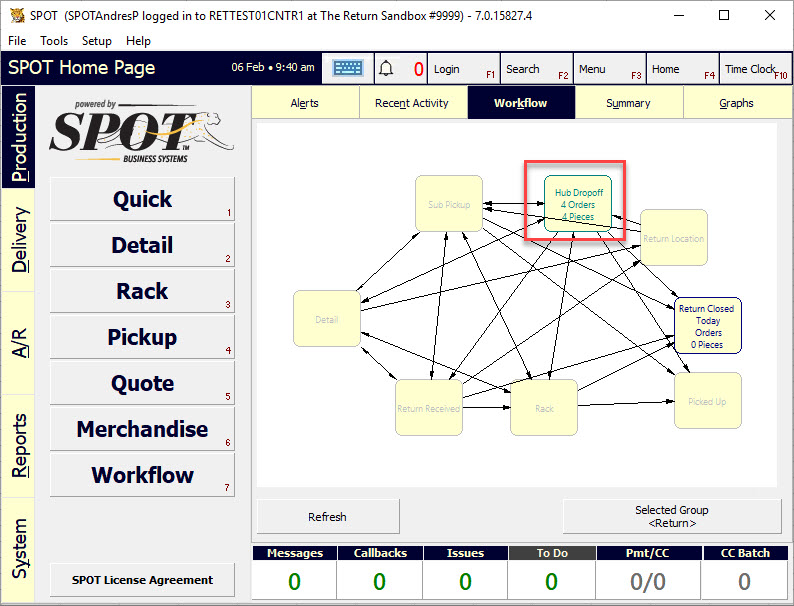

Start by navigating to the Workflow button in SPOT and entering your PIN

.png)

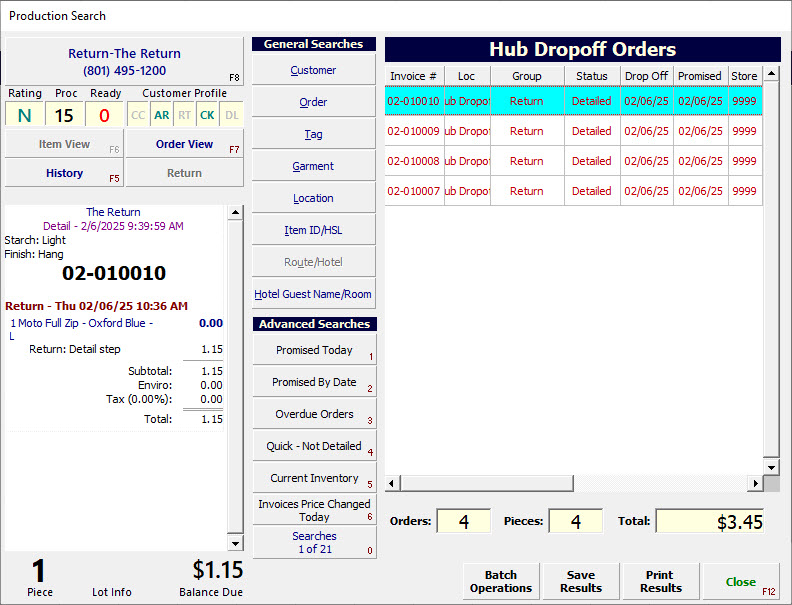

Select Hub Drop-Off from the available workflow steps

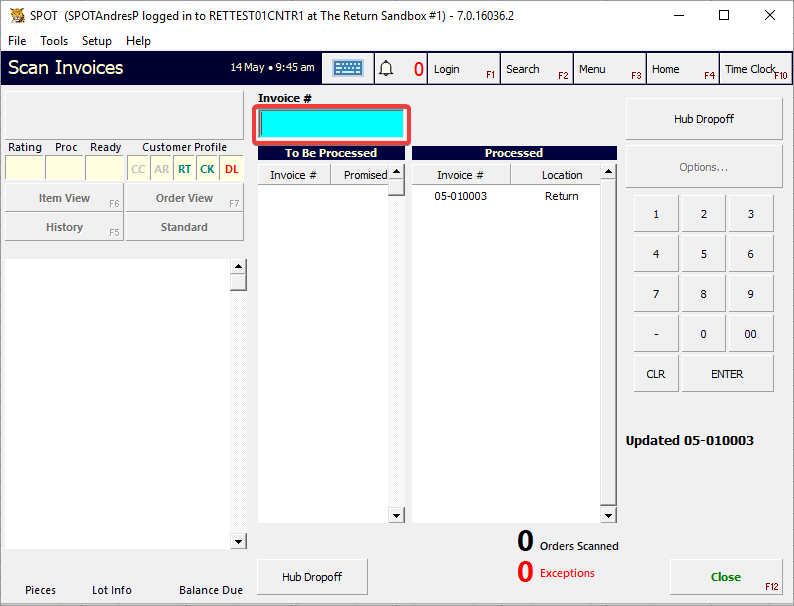

Scan the 2D Code from the printed invoice for the required package.

New Invoices

Completing a successful scan of a QR code from a Non-Owned Sub store will trigger SPOT’s printer to produce two new invoices. Store staff should affix the new invoice on top of the old copy onto the package box, as it now contains important, updated information.

Scanning to Return Location (Optional)

After successfully processing all returns into the Hub store system, store staff can scan each printed invoice into the Return Location step (The 2nd invoice copy that was generated at the Hub store, when dealing with sub store transfers). Scanning into the Return Location step allows you to track where each package is being held.

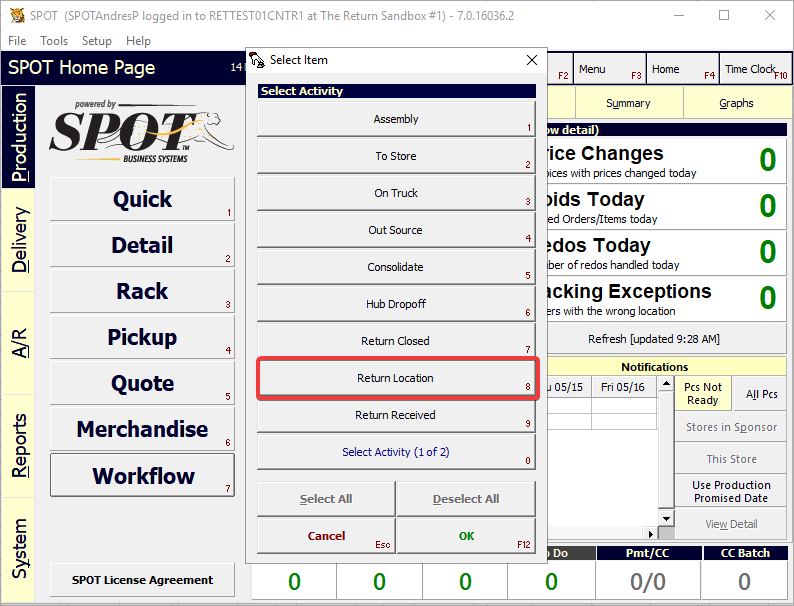

Start by navigating to the Workflow button in SPOT and entering your PIN

.png)

Select Return Location from the available options

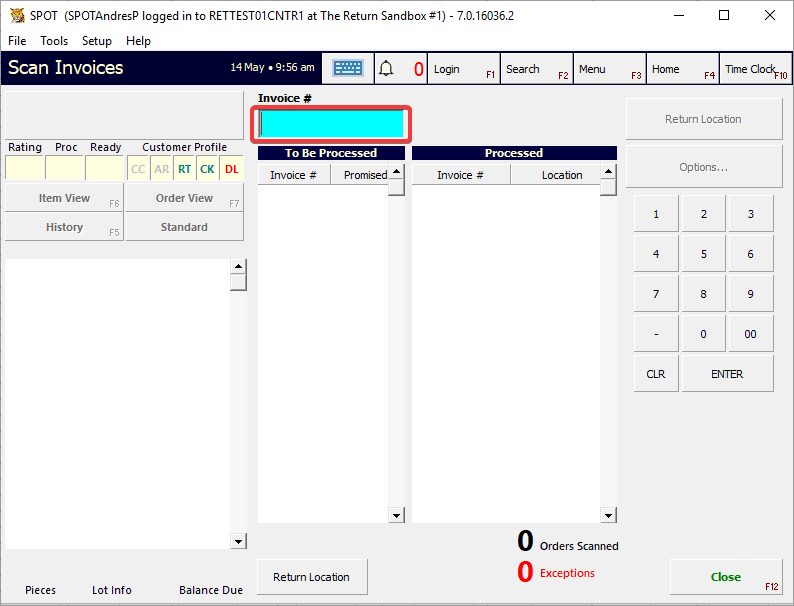

Scan the 2D barcode of all the available invoices for the processed returns

Viewing current inventory

To review current ready return inventory, awaiting driver pick-up, store staff can access the Hub Drop-Off step in the Return workflow.

Issues at pickup

Should any issues arise when the LTL driver arrives on location to retrieve the returns, please e-mail Brenda@bainterests.com for further assistance.

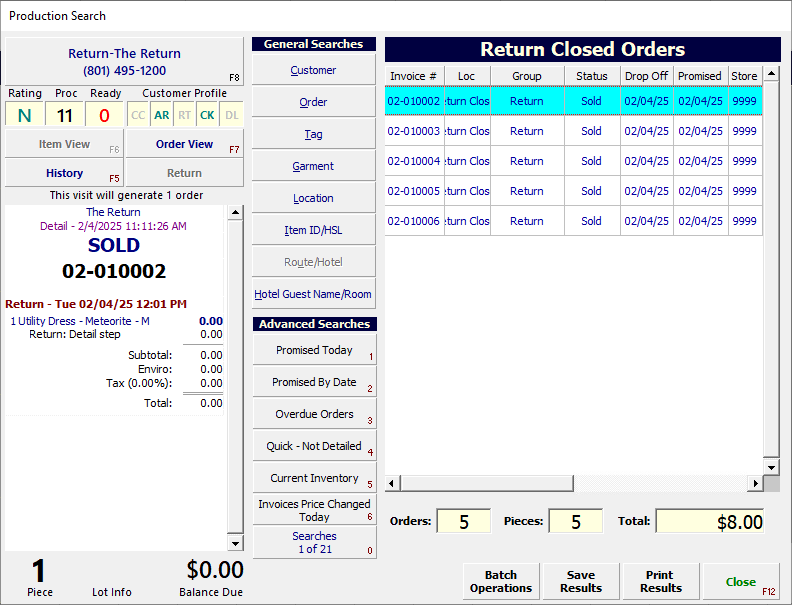

Final return closed scan

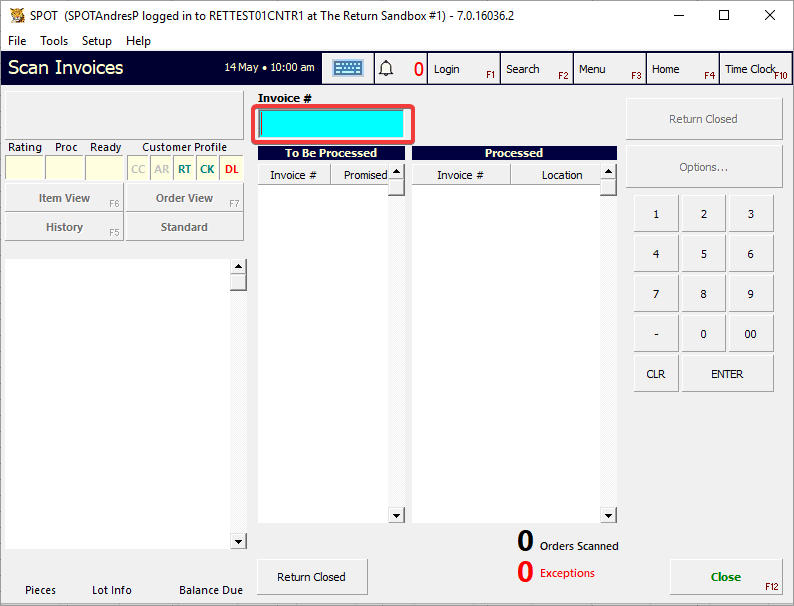

Once the LTL driver has arrived on location to retrieve the pallet of boxed returns, store staff must perform the final Return Closed Scan to complete the process.

Start by navigating to the Workflow button in SPOT and entering your PIN

.png)

Select Return Closed from the available workflow steps

Scan each 2D Barcode into the Return Closed scan step

Manifest Print

To complete the pick-up of all Hub orders, the LTL driver must be provided with the final printout of the delivery manifest.

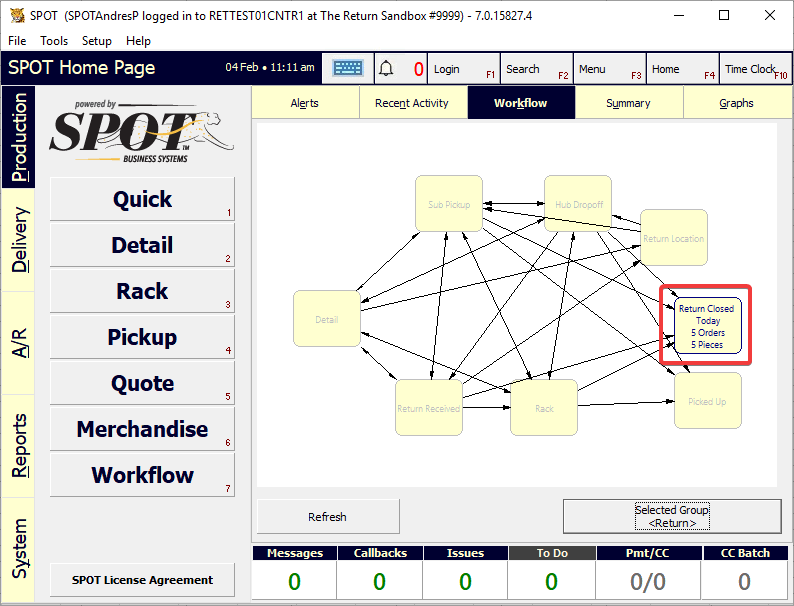

Start by accessing the Return Closed workflow step in the Return production workflow

Select Print Results in the bottom right to print the final delivery manifest and provide it to the LTL driver

The LTL driver can now load the pallet of returns unto the truck and the return process is considered completed.